Soil Vapour Extraction and Air Sparging

By Dr. Yashpal Singh

Chairman, The Wealthy Waste School India

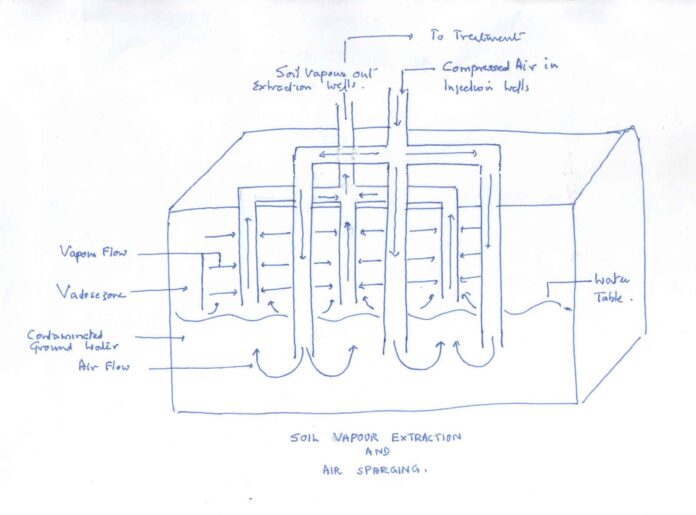

Soil Vapour extraction involves drilling into the contaminated soils to a depth above the water table which must be 3 feet below the ground level. Some EPA references indicate at least 10 feet below ground (see below). The vacuum pumps suck the vapour and air through the soil and the vapours are taken for treatment. Sometimes the ground is paved to prevent suction of ambient air.

The Enhanced Density Driven Convection technology, a continuous injection remediation technology (EDDC), is a modification of the soil vapour extraction / air sparging process where the extracted vapours with the accompanying air are treated to remove moisture, heated to approximately 95o F. and microfiltered in Activated Carbon filters to remove volatile impurities like VOC’S. The treated Air is again injected in the well with suitable antifouling agents to prevent calcite fouling.

Air sparging is an in-situ remediation technology which involves the injection of contaminant free air in the subsurface saturated zone, enabling a phase transfer of hydrocarbons from a dissolved state to a vapor phase. The air is than vented through the unsaturated zone. It is generally used together with soil vapour extraction but can be used with other technologies also. Soil vapour technology (SVE) also known as soil venting or vacuum extraction is also an in-situ remediation technology that reduces concentrations of volatile constituents in petroleum products adsorbed to soils in the unsaturated (vadose) zone. In this technology vacuum is applied through wells near the contaminated zones. Volatile components of the contaminant mass evaporate and the vapours are drawn towards the extraction wells. Extracted vapour is then treated as necessary (commonly with carbon adsorption) before being released into the atmosphere. Increased air flow may also induce some biodegradation. SVE offers proven performance, readily available equipment and easy installation, it involves short treatment times of usually 6 months to 02 years, cost $ 20 to 50 (1994 report) for every ton of contaminated soil and can be combined with other technologies. Concentration reductions of more than 90% are however difficult to achieve and may also involve high cost for treatment of vapours. It can only treat the unsaturated zone soils. Other methods may be needed to treat the saturated zone soils and ground water.

The soil type, permeability and the level of ground water table are important criteria in determining the suitability of SVE. The permeability should be generally be greater than 10-6 cm/sec. and the ground water table at greater than 10 feet below the ground level to prevent upwelling in the wells. For higher water tables, a pump is installed to lower the water level and increase the vadose zone.

Air sparging also needs short treatment times (1 to 3 years), costs $ 20 to $50 per tonne of saturated soil and is less costly than above ground treatment systems. It requires no removal, treatment, storage or discharge conditions for ground waters and can enhance the removal by soil vapour evaporation.

Treatment of extracted vapours involves Air Water separation followed by micro filtration (Preferably Activated Carbon Filters). Sometimes tiny microbes are used to break down vapours or the vapours can be destroyed by heating to high temperatures.

In situ thermal remediation processes can be used to enhance the recovery of organic contaminants specially gasoline and diesel and chlorinated solvents. The main mechanism is an increase in vapour pressure with temperature which allows these chemicals to be removed in the vapour phase. Enhanced solubility and decreased adsorption at higher temperatures also contribute to the recovery of these chemicals. Temperature induced viscosity reduction, increased relative permeability and decreased capillary forces also pay an important role. The residual contaminants can be degraded by the soil microbes which can survive high temperatures. Thermo physical reactions can partially or fully oxidise some organic contaminants.

Non aqueous phase chemicals, which may continue to contaminate ground water for centuries, can be removed successfully by employing steam enhanced extraction. Steam is injected in the subsurface to heat the target zone of contamination to the boiling point of water. NAPL (Non-Aqueous phase liquids) and vapours are constantly pumped from the other wells. This has been safely used in the recovery of Trichloro Ethylene, non-aqueous phase liquids and gasoline from soils and the removal of their soluble fractions from ground water.

Thermally enhanced extraction is an innovative combination of ground water extraction, soil vapour extraction, steam injection, hot air injection and control techniques for accelerated and complete remediation. In a case where Trichloro ethene, a dense non aqueous phase liquid (DNAPL) had accumulated 50 feet below the surface in the saturated zone after leakage from trenches, 11 days of thermal injection followed by 12 days of ambient air injection accompanied by ground water extraction and soil vapour extraction in all the phases resulted in a 98% reduction in concentration in the channel soil and a 50% reduction in soil above the aquitard. In another experiment with NAPL contamination, steam injection resulted in a decrease of 95% in steam swept areas with the final concentration in ground water close to the clean up levels.

The six-phase heating system (SPH) can also remove DNAPLS from the subsurface. It uses in situ electric resistive heating and steam stripping to achieve sub surface remediation. The systems raise the subsurface temperatures to the boiling point of water and is effective in all soil types and can be used for low permeability soils, DNAPL and LNAPL remediation, Cold regions treatment, heavy hydrocarbon mobilisation, rapid clean up, enhanced biological remediation and in aquifer heating.

Radio frequency antenna heating has also been safely utilised to accelerate remediation of contaminated sites together with soil vapour extraction, ground water aeration (air sparging), product recovery and bio remediation. Heating designed to heat the vadose zone causes changes in the physical, chemical and biological properties of soils making them more amenable to remediation efforts. Biodegradation rates have been reported to increase 2 to 10 times and in another case the cleanup time has been reduced to within 06 months against the normal time of 2 to 3 years at ambient soil temperatures.

Heat and vacuum can also be simultaneously applied to subsurface soils through heaters or vacuum pumps. As the soil is heated, the volatile contaminants in soil are vaporised by a number of mechanisms including evaporation into the air streams, steam distillation into the water vapour stream, boiling, oxidation and pyrolysis. The vaporised components (water, contaminants and natural organic components) are drawn by the vacuum pumps. The soil can be heated to high temperatures (>5000C) for long times. In practice most of the contaminants are destroyed in soil. Those that are not destroyed are removed from the vapour stream through air pollution control systems.

The Dynamic underground stripping system is a form of thermal treatment which utilises boilers to generate steam which is pumped into injection wells that surround the contaminants. The steam volatilises and mobilises the contaminants towards a central network extraction well where it is vacuumed at the surface.

The In well aeration/stripping technology is utilised for removing VOCs from ground water. Pressured air is injected into a contaminated area through a well. The combined stream of air bubbles and water helps in transferring the contaminants from the aqueous phase to the vapour phase in the bubble and are vacuumed to recover the contaminated vapours for treatment. The ground water flows back into the aquifer. Studies have indicated a reduction of 99.9% at 50 feet down gradient, 99.9% at 60 feet down gradient and 99.3% at 40 feet down gradient.

Volatile organic compounds (VOC’s) can be stripped from the dissolved and adsorbed phases to the vapour phase by injecting air bubbles below the water level. The injected air containing VOC’s rises to the vadose layer and eventually into the atmosphere. In many cases soil vapour extraction is used together with air sparging to collect and treat these VOC’s. The process also oxygenates ground water which stimulates the aerobic biodegradation in the saturated and vadose zones.

Bio remediation techniques utilise contaminants as the food source. It may require larger treatment times but facilitates ground water to be treated without being brought to the surface at significant cost savings. Contaminants are degraded, although some can be transformed into more toxic compounds. These techniques have been successfully utilised to remediate ground water contaminated with petroleum hydrocarbons, solvents, pesticides, wood preservatives and other organic chemicals. Heating the bio remediation site such as warm water injection may speed up the remediation process. Air sparging below the water level (Oxygen enhanced bio remediation) increases the rate of oxidative degradation. It is usually used in conjunction with Soil Vapour Extraction or bio venting to enhance the removal of volatile compounds. Dilute H2O2 and solubilised nitrate may also be circulated in the contaminated zone to enhance the rate of oxidative destruction.

Methane can be used instead of sparged air to enhance the co-metabolism of chlorinated organics. Air sparging has a medium to long duration which may extend to several years.

Bio venting is the process of aerating soils to stimulate in situ biological activity and promote bioremediation. Bioventing typically is applied in-situ to the vadose zone (i.e., unsaturated soils) by injecting oxygen in the form of air. Bio venting systems are designed to maximise biodegradation while minimising volatilisation. This technology is applicable to any chemical that can be aerobically degraded but has been used largely in petroleum contaminant source within the vadose zone, thereby preventing future and/or continued contamination of ground water.

A typical bio venting system injects air at a low rate into the vadose zone. It is related to the process of soil vapour extraction but differs from it in that while bioventing is designed to maximise biodegradation of aerobically degradable organic compounds with some volatilisation, soil vapour extraction on the other hand is designed to achieve maximum degradation through volatilisation and only some biodegradation.

Bioventing reduces vapour treatment costs which typically range from 50 to 80% of total remediation costs.

Bioventing is most effective in quickly treating the most toxic, soluble and mobile constituents in fuels (benzine, toluene, ethyl benzenes and xylenes). Results are typically seen in less than a year. (97% in the first year).

The average cost for design, installation and one year of operation and monitoring at a single vent well bioventing site was less than $60000 per site based on actual costs. At nearly half the sites tested by the Air Force, nearly half of the pilot systems tested were converted into full scale remediation systems.

Based on Air Force application of bioventing, the total cost of in- situ soil remediation using bio-venting was $10 to $60 per cubic yard of contaminated soils. Smaller sites (<500 cubic yards) were about $60 per cubic yard and larger sites (<10,000 cubic yards) were about $10 per cubic yard.

The cost of bio venting goes down with depth of contamination.

Bio venting is best applicable if the contaminants of concern are aerobically biodegradable like crude oil, waste oil, heating oil, petroleum based hydraulic third, diesel, jet fuel, gasoline, Aviation fuel, alcohols, acetone etc. and the majority of the contaminants mass is above the ground water level (i.e. vadose zone), the depth to the average ground water level is more than 3 feet and contaminated soil volumes are more than 500 cubic yards, soil gas displays low O2 (Less than 5% vol/vol) and high Co2 (>2%) v/v) profile compared to nearby uncontaminated area. Bioventing systems work better in soils that are more permeable.

Air stripping is the process of forcing air through polluted ground water or surface water to remove harmful chemicals. The air causes the contaminants to evaporate. These are collected and then cleaned. It is generally used as part of the pump and treat system. The stripper usually consists of the ‘air stripper’ which is a tank filled with a packing material made of plastic, steel or ceramic. The polluted water is pumped in the tank and sprayed over the packing material. The water trickles down through the spaces and the air is blows upwards. The air brings about evaporation and the gases collect at the top of the tank and are cleaned. Air stripping is safe.

Air strippers can be brought to the site. Depending on the site characteristics clean ups may take many years to complete. It works best on chemicals that can evaporate like solvents and fuels and can remove 99% of these contaminants. It cannot remove metals, PCB’s or other chemicals that do not evaporate.

Soil vapour extraction and Air sparging may incur high costs of electricity and fuel consumption due to long term operation and maintenance, release contaminant vapours and require disposal of wastes. All these impact the environmental foot print. Electricity consumption by a typical SVE equipment operating for 3 years (excluding system design and construction) could emit 184 tons of carbon dioxide which is equivalent to the electricity used by 22 American homes for over one year

Soil Vapour Extraction or Air Sparging operations could be made green by

- Reducing electricity consumption through pulsed rather than continuous air flow.

- Decreasing fugitive emissions of contaminated vapour due to properly maintained well seals.

- Lowering the need for fresh water use as a result of recycling condenser water for use in supplemental cleaning.

- Reducing material consumption and waste generation through GAC filter regeneration.

- Reducing noise disturbance to wildlife and communities through use of sound proofed equipment housing.

References:

- United States Environmental Protection Agency. 2012 Office of Solid Waste and Emergency Response. (5102G). EPA 542-F-12-018, September 2012. www.epa.gov/superfund/sites; cluin.org

- Insitu Treatment of Hexavalent Chromium and VOC’S using recirculating wells McKeon, T., English C.J. and Petorson S.R., 2000 in ‘Abiotic Insitu Technologies of Ground Water Remediation”, Conference Proceedings, August 2000, EPA/625-R-99/012. https://cfpub.epa.gov/si/si_public_record_report.cfm?Lab=NRMRL&dirEntryId=64057

- https://www.epa.gov/sites/default/files/201504/documents/a_citizens_guide_to_soil_vapor_extraction_and_air_sparging.pdf

- https://www.geoengineer.org/education/web-class-projects/cee-549-geoenvironmental-engineering-winter-2013/assignments/vapor-extrusion

- Mechanisms in Insitu Thermal Remediation. Davis, Eva, L. 2000 in “Abiotic Insitu Technologies of Ground Water remediation”, Conference Proceedings, August 2000, EPA/625-R-99/012. https://cfpub.epa.gov/si/si_public_record_report.cfm?Lab=NRMRL&dirEntryId=64057

- Remediation of Soils and Ground Waters using steam enhanced Extraction, Udell Kent. S. 2000 in Abiotic Insitu Technologies of Ground Water remediation,” Conference Proceedings, August 2000, EPA/625-R-99/102. https://nepis.epa.gov/Exe/ZyPDF.cgi/30004TG3.PDF?Dockey=30004TG3.PDF

- Field Demonstrations of Thermally enhanced Extraction, Stewart Lloyd. D 2000 in “Abiotic insitu technologies of ground water remediation”, Conference proceedings, August, 2000, EPA/625-R-99/102 P.25. https://nepis.epa.gov/Exe/ZyPDF.cgi/30004TG3.PDF?Dockey=30004TG3.PDF

- Insitu DNAPL Remediation using six phase heating, Trowbridge Brett, 2000, in “Abiotic insitu technologies of ground water remediation”, Conference Proceedings, August, 2000, EPA/6025-R-99/102 P. 26. https://nepis.epa.gov/Exe/ZyPDF.cgi/30004TG3.PDF?Dockey=30004TG3.PDF

- F. Heating Technology for soil remediation, Price S.h and Kasevich S. 2000 in “Abiotic insitu technologies of ground water remediation”, Conference Proceedings, August 2000, EPA/625-R-99/102 P. 27-29. https://nepis.epa.gov/Exe/ZyPDF.cgi/30004TG3.PDF?Dockey=30004TG3.PDF

- Thermal Conduction heating for insitu thermal desorption, Stegemeier, G.L. Vinegar, H.J. 2000 IN “Abiotic Insitu Technologies of ground water remediation”, conference Proceedings, August 2000, EPA/625-R-99/102 P. 30 https://nepis.epa.gov/Exe/ZyPDF.cgi/30004TG3.PDF?Dockey=30004TG3.PDF

- Interagency DNAPL Consortium, Early, T. and De vane, P. 2000 in “Abiotic insitu technologies of ground water remediation,” conference Proceedings, August 2000, EPA/625-R-99/102 P. 37-41. https://nepis.epa.gov/Exe/ZyPDF.cgi/30004TG3.PDF?Dockey=30004TG3.PDF

- In-well Aeration/Stripping Technology: Overview and Performance Results. M.C. Keon, T., Johnson, J. and Bach. C., 2000 in Abiotic insitu technologies of ground water remediation”, Conference Proceedings, August 2000, EPA/625-R-99/102 P. 50-53. https://nepis.epa.gov/Exe/ZyPDF.cgi/30004TG3.PDF?Dockey=30004TG3.PDF

- Air sparging for ground water remediation of Toluene and other V.O.C.’s: Case studies Moore, A., 2000 in Abiotic insitu technologies of ground water remediation conference Proceedings, August 2000, EPA/625-R-99/102 p. 54 https://nepis.epa.gov/Exe/ZyPDF.cgi/30004TG3.PDF?Dockey=30004TG3.PDF

- Remediation Technologies Screening Matrix and reference guide, Version 4.0, 3.9. Insitu Biological Treatment for groundwater, surface water and leachate. FRTR 2012.

https://nepis.epa.gov/Exe/ZyPDF.cgi/P100FEB3.PDF?Dockey=P100FEB3.PDF

- Air Force Center for Engineering and the Environment. Bioventing_filter/AFD-070927-119.jpg. Bio venting. ‘Bio venting performance and cost results from multiple Air Force Test Sites”. https://apps.dtic.mil/sti/tr/pdf/ADA324017.pdf

- S. Environmental Protection Agency. ‘Air Sparging’ Excerpt from chapter VII of Ousts publication: How to evaluate Alternative Clean-up Technologies for underground storage tank sites: A guide for corrective action plan reviewers. (EPA 510-B-95-007). https://www.epa.gov/ust/how-evaluate-alternative-cleanup-technologies-underground-storage-tank-sites-guide-corrective

- S. Environmental Protection Agency 2001- A citizens guide to Air stripping. EPA 452-F-01-016. https://nepis.epa.gov/Exe/ZyPDF.cgi/10002SQN.PDF?Dockey=10002SQN.PDF

- United States Environmental Protection Agency 2010, Green Remediation Best Management Practices-Soil vapour extraction and Air sparging, Office of solid waste and emergency response (5203P), EPA 542-F-10-007, March 2010. https://semspub.epa.gov/work/HQ/147896.pdf

- Interagency DNAPL consortium. Early T. and De Vane, P 2000 in Abiotic insitu technologies of ground water remediation” Conference Proceedings, August 2000, EPA 625/-R-99/102, pp 37-41 Document Display | NEPIS | US EPA

- https://www.frtr.gov/matrix2/section4/4-7.html

- https://gost.tpsgc-pwgsc.gc.ca/tfs.aspx?ID=26&lang=eng#infoMenu1

- https://vim-1.itrcweb.org/soil-vapor-extraction-sve-tech-sheet/

- https://www.xdd-llc.com/soil-vapor-extraction/

- http://widit.knu.ac.kr/epa/ebtpages/Treatment_n_Control/Treatment_Technologies/Soil_Vapor_Extraction/site2.htm